We're not perfect, but we're always looking for ways to be better for our customers, the environment, our industry and future generations.

In association with Carma, we're planting a tree every time someone places an order on our online stores. Below is a live update on how many trees we've planted thanks to our customers so far:

Sustainable Ski & Snowboard Clothing Brand Oneskee.

We are committed to continually working to improve our sustainability. We do this through eco-friendly production, and also do what we can in other areas of the business where possible. We believe this is the duty of all brands, and is now rightfully an expectation for all consumers when making their purchasing decisions.

The vast majority of our products now utilise recycled fabrics, and all of our packaging is now fully recyclable.

Polyester blends well with natural fabrics, like cotton. Since recycled polyester has been available since the early 1990s, it is more widely available and is similarly priced to its virgin counterparts. Using recycled polyester lessens our dependence on petroleum as a source of raw materials, utilises waste and reduces greenhouse gas emissions from manufacturing. In addition, by using recycled polyester we are able to promote new recycling streams for polyester clothing that is no longer wearable.

Nylon is one of the strongest plastics we use in our products. When we need a super lightweight fabric, nylon is vital for its strength. But nylon is a petroleum-based material, and producing it has a high cost in energy and greenhouse gases. Incorporating as much recycled nylon as we can lessens our dependence on virgin petroleum as a raw material source, helps eliminate discarded material and reduces greenhouse gas emissions from manufacturing. Using recycled nylon also promotes new recycling streams for nylon products that are no longer functional.

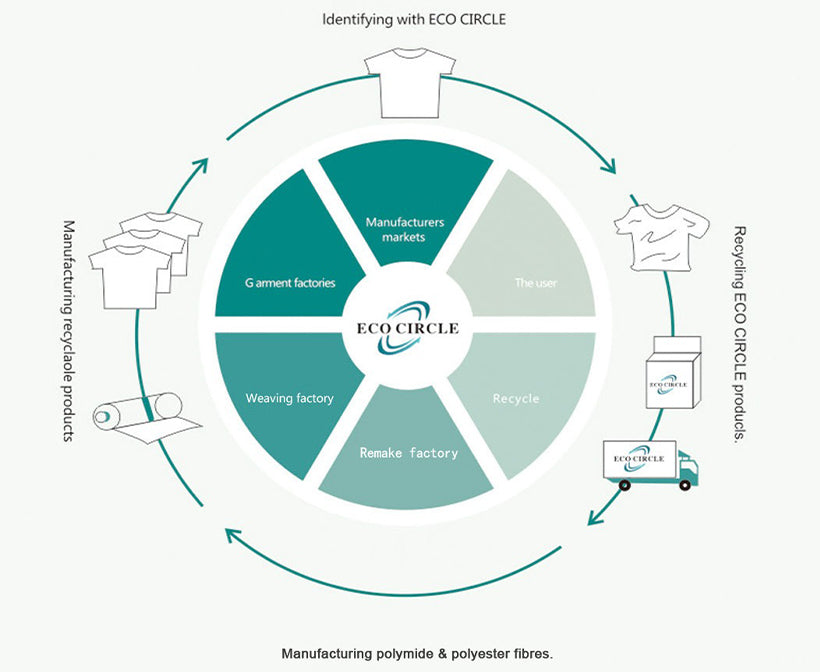

Our products use 'ECO CIRCLE™ Fibres', a circulating type recycling system for polyester products. ECO CIRCLE™ recreates new fibre from used fibre and other products without degrading the quality. This makes it possible to reduce the amount of garbage oil consumption and greatly reduces CO2 emission and energy consumption. After textile products are collected they are broken down and processed to create new polyester fibre with no compromises in quality or variation.

Some of our Acclimate™ products use Dupont Sustans Sorona® Aura. This is a new type of eco-friendly bio padding, made from Sorona polyester fibre combined with renewable biological fibre. It is a three dimensional helical structured fibre and comes from a natural renewable resource, reducing our dependence on fossil fuels and petroleum based products. Sorona® is a bio-based and functional polymer for textile material fibres, which is made in part with annually renewable plant based ingredients. Its unique molecular structure and crystalline morphology give unique properties in fibres with Sorona.

Our garments do not contain AZO dyes. AZO dyes are a type of direct dye - meaning that they colour the fibers "directly” and are one of the main types of dye used by the textile industry. They are known to be potential carcinogens. Studies have found that the dyes are resistant to municipal waste water treatment facilities and pass into the environment relatively unchanged. Textile mill effluent contains 5%–20% of original dyestuff, plus salt and dye fixing agents. Some AZO dyes break down during use and release chemicals known as aromatic amines, some of which can cause cancer–typically bladder and liver cancers, but studies also link them to breast cancer.

All Oneskee products are designed in the UK by a small team of designers and technical experts, before being produced in our factories overseas. We engage in a range of due diligence activities to promote and sustain fair labour practices, safe working conditions and environmental responsibility in the finished-goods factory.

We have a close relationship with our factory and are in regular discussion about ways to improve products, overcome challenges and get the best results for ourselves, our factory and our customers.

As our products are manufactured overseas, we are required to transport them from our factories to our various fulfilment centres globally. To do this we have chosen shipping by sea rather than the quicker air alternative. A Defra study concludes that two tonnes of freight carried for 5,000km by a small container ship creates 150kg of CO2e (a measure of relative global warming potential) compared to 6,605kg of CO2e if the freight is carried by plane for the same distance.

We will continue to work hard to do our part so that future generations can experience the joys of our planet.